SOLUTIONS

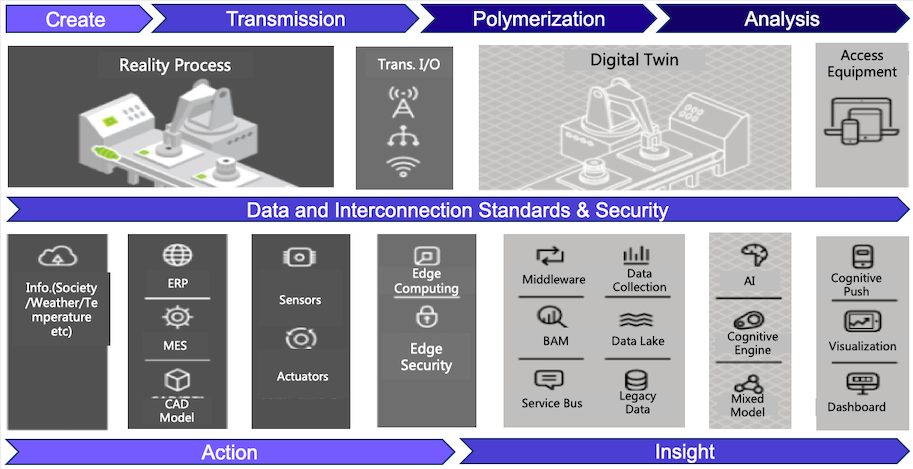

Digital twins meet business needs through data collection, integration, analysis, and optimization of physical and biological assets, forming a virtual-real mapping of physical world asset objects and digital space business applications, and ultimately supporting the development and implementation of various business applications. The future development will realize real-time conversion in the fields of physics, digital and biology:

• Physics widely connects hardware and system-on-chip.

• Digital will fully support software systems and digital twins

• Biotechnology will provide new user experiences and intent-based automation and networking across fields and industries in various new ways.

(Figure 1) Digital twin system framework

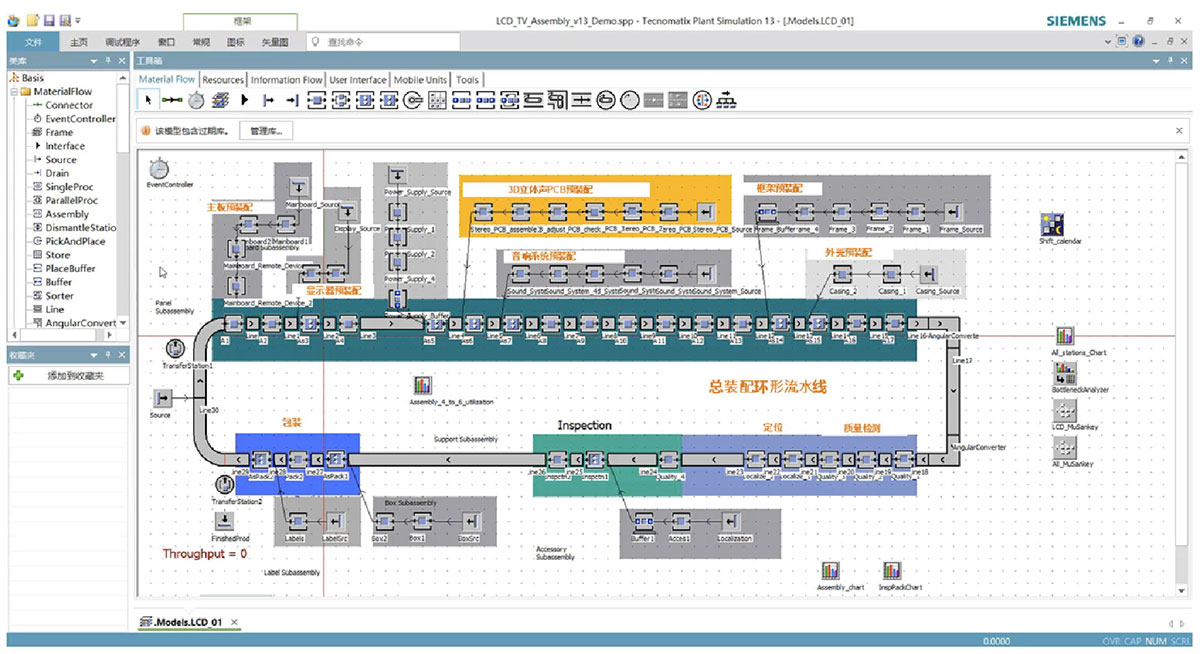

Digital twin solution is based on the product life cycle digital main line created by the actual industrial production process realizes the synchronization of the intelligent manufacturing full life cycle process and the virtual simulation system; through advanced technologies such as process simulation, robot automation simulation, virtual debugging, and data collection etc., which can be familiar with the equipment and process flow of the production process; mainly includes software systems, intelligent display systems, robot simulation software, etc.

The software platform enables 3D modeling, simulation, and virtual debugging of concepts that include multiple physics and automation-related behaviors commonly found in automation equipment.

Through the digital model to simulate the movement and working state of the automation equipment, the mechanical and electrical linkage virtual debugging is realized. Through the virtual and real connection of the twins, the data is continuously iterated and the model is continuously optimized to obtain the best solution for the automation equipment.

(Figure 2) The practical application scenario of the digital twin virtual production line in cooperation with Siemens

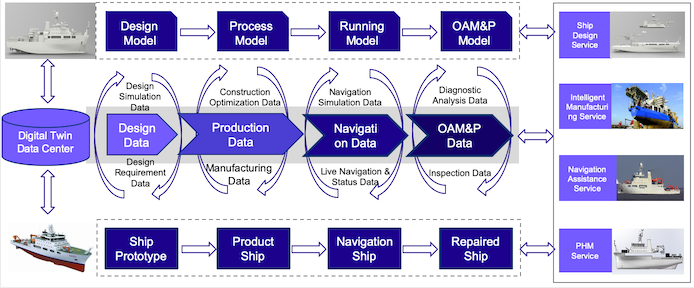

(Figure 3) Application scenarios of refined design, intelligent manufacturing, navigation assistance, fault prediction and health management based on digital twins

Scan the QR code to read on your phone

Links:Deutsche Messe丨Siemens丨SHANTAC

Copyright © 2020 Shandong Hannover Industry Technology Academy ICP:20013427 Powered by www.300.cn